Thank you for participating in the Creating Good Jobs Trade Fair

Thank you very much for visiting our booth at

"2022 Creating Good Jobs Trade Fair" held at Tokyo Big Sight.

At the event, we exhibited our original "glass that can be screwed on," aerial displays, and

manufactured products of low reflection film, etc.,

and we have received many inquiries.

On behalf of all parties involved, we would like to express our deepest gratitude. Thank you very much.

If you have any questions that you couldn’t ask at the Fair,

please do not hesitate to contact us through the inquiry form.

We look forward to hearing from you.

News

The Tokyo Shimbun newspaper featured our story on December 2, 2022

We have listed our qualified invoice issuer registration number in the company profile.

A company that always accommodates customers' needs and meets society's expectations with originality and ingenuity.

Proposal Power

One individual's proposal may "add" up, but when we all think together, it's possible to create a surprising processing technology by "multiplying" ideas.

Our manufacturing style is to propose and solve each and every need with the combined wisdom of all our employees.

In addition to daily work, we hone in on all our employees' proposal skills through employee education and study sessions, so that we can all tackle the same issues together and demonstrate our specialized skills.

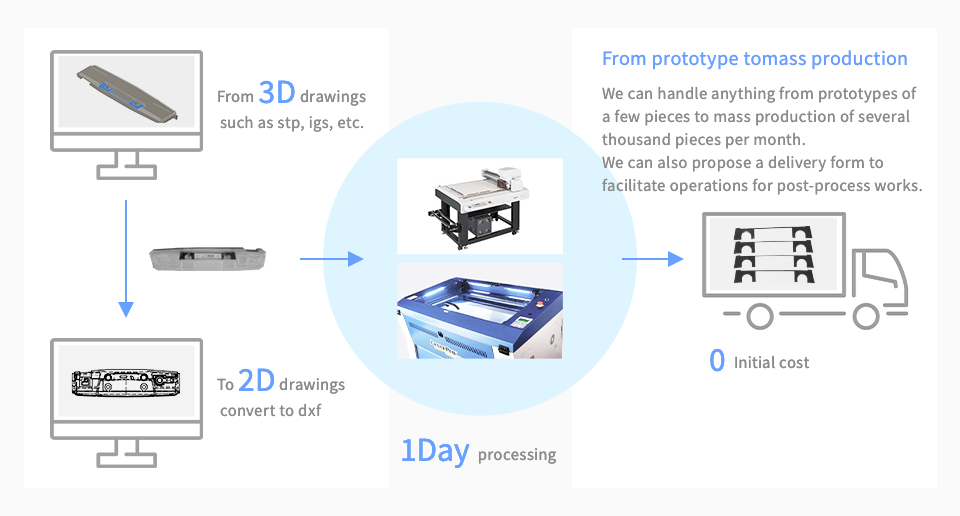

MBD (Model Based Development) support for mold-less and plate-less processing (initial-less).

More freedom in manufacturing with "3-2-1-0 Processing."

-

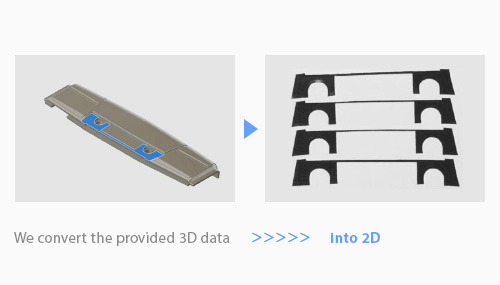

- We convert the 3D data provided by the customer into 2D. We can create core structural components in as short as 1 day and with 0 initial cost.

[Benefits]

- Improvements that were previously impossible, in terms of shapes, short delivery times, small lots, cost reductions, and better work efficiency will be achieved!

- Reduced waste due to mold-less design. Contributing in preventing environmental pollution.

- Since it can be digitally managed, working with BCP will be easier.

- We convert the 3D data provided by the customer into 2D. We can create core structural components in as short as 1 day and with 0 initial cost.

Why not make everything from prototyping to mass production hassle-free?

We convert 3D data into 2D data to create sheets, cushions, double-sided tapes, and more. Complex shapes, finishes that require precision, and complicated components can also be handled.

Please feel free to contact us first for more information.

Processing Examples

-

-

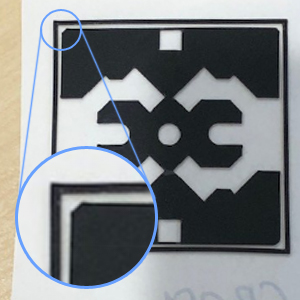

Half-cut

Capable of R-shaped cuts and other fine shapes

that were difficult to achieve

with conventional molds -

-

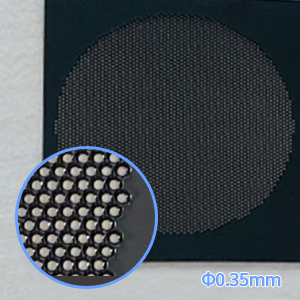

Speaker Sheet

Fine holes that cannot be

processed with molds

can be created -

-

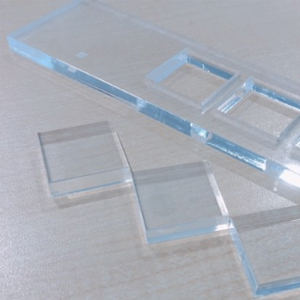

Acrylic Cutting

Capable of cutting acrylic material

of 5mm or less in thickness.

Engraving of letters, etc. is also possible.

Our Business Partners

INOAC Group, IWATSU Group, NEC Group, SAXA Group, Sansuisha,

TAKAMISAWA CYBERNETICS, NAGASE ABRASIVE MATERIALS, Laird Technologies Japan, Panasonic Group,

HERZOG Japan, Mipox, Mitsubishi Chemical, MEIKO Group, YUASA Group,

RYODEN, Watanabe Electric Group, Ministry of Defense/Japan Ground Self-defense Force, JRTT,

and 30 other companies (titles omitted)

Considering our customers’ needs, we "manufacture" in a way that goes beyond culture and customs.

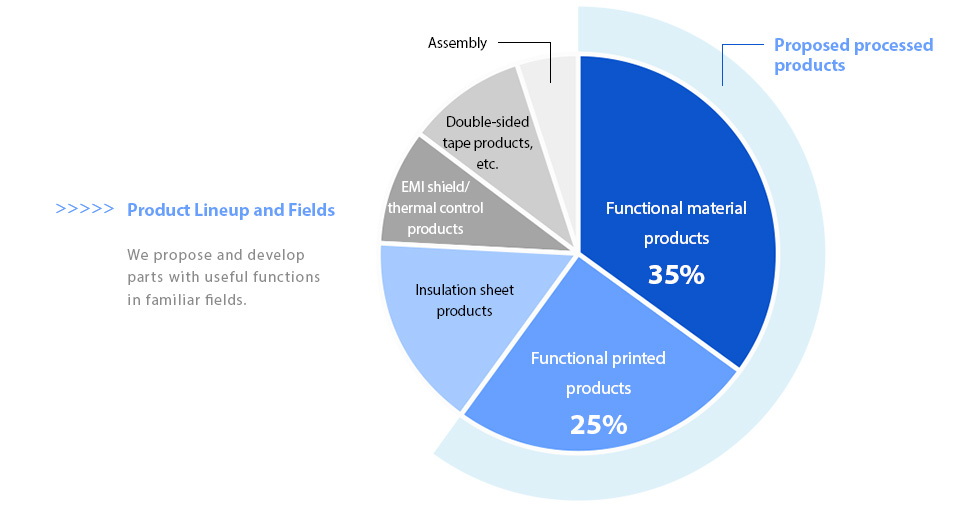

Services

We have proposed and developed parts with useful functionality in fields that are part of our daily lives such as,

railroads, transportation, stations, public facilities, as well as various industrial products.

-

Examples of Product Development

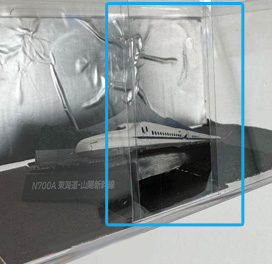

- [Railroads & Transportation]

Development, processing, and delivery of materials for signage, soundproofing walls, sound insulation walls, and more

[Stations & Public Facilities]

Development, processing and delivery of wall and partition materials, etc.

[Various Industrial Products]

Development, processing and delivery of parts and materials for ATM, cashless devices, drones, and security devices

Examples of Products We Offer

- (1) Aerial display / (2) Floating display

- (3) Ultra low reflection film / (4) Mossmite

- (5) MIRAI PIX

- [Railroads & Transportation]

-

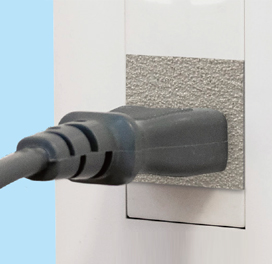

"Glass that can be screwed on"

is our unique product

*We propose an easy way to fix fragile glass into place. Click PDF for more details.

-

Mossmite

Ultra low reflection film

*It uses a biomimetic material that reduces reflection to near non-reflective levels when applied to glass or acrylic.

-

MIRAI PIX

Our proposal for an aerial display equipment

*This image of a floating display is for reference only.An aerial imaging type display. This new generation aerial display is of a level that can withstand use in brightly lit stores.

"Glass that can be screwed on" is our unique product

We propose an easy way to fix fragile glass into place. Click PDF for more details.

Together with everyone, we are moving forward, one step at a time.

About Us

Keeping in mind that "things" are created with intention, we will work together with our customers,

business partners, and society to create a more livable and comfortable society.

-

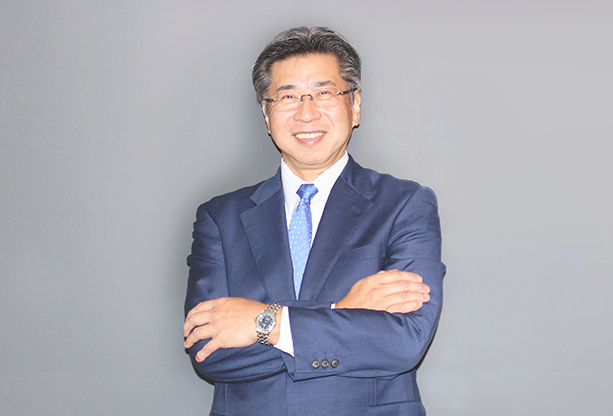

Message from Our President

Glanz Techno Works Corp. is a new company, established in May 2019.

Based on the principles of knowledge, humanity, and courage,

we hope to be an organization that boldly takes on new challenges.

We would like to become your partner, thinking of new ideas and improving together with you,

so that we can create something meaningful for the world.

Our aim is to create a brilliant (Glanz) life, a life full of “wow" moments, surprises and new discoveries.

We look forward to your guidance and support.October 1, 2019

CEO Tetsuo Miyamoto

Biography of President

Born in November, 1963

After graduating from the Faculty of Engineering at university, he worked part-time for a year at a foreign securities firm and saved up enough money to go on to higher education.

After graduation, he worked for a chemical company as a development engineer in the mastering process of optical discs (mastering and stamper creation).

After about 4 years, he moved to the mechanical parts industry as an engineering sales representative where he continued to build a successful track record. Then in 2019, he starts this current company.

Making the most of his experience as an engineer, he takes on the challenge of creating new products, as he lives by his motto, "be a better version of yourself now and tomorrow, than you were yesterday."

-

Corporate Profile

Corporate Name Glanz Techno Works Corp. Registration Number

Qualified Invoice Issuer Registration Number

T3-0124-0103-5372President Tetsuo Miyamoto Established May 30, 2019 Capital 10 million yen Location 1-30-2 Higashi Izumi, Komae-shi, Tokyo

201-0014Number of employees 8 Phone +81-3-5761-8030 FAX +81-3-5761-8856

-

SDGs - Environmental Initiatives

- We are committed to SDGs with awareness, as we are all residents of the earth. We start with doing all that we can.

We will take on even the most difficult requests.

Contact Us

Estimates and consultations are free. Please feel free to contact us by phone (weekdays from 9:00 to 17:00) or by e-mail.

Privacy Policy

At our company, we recognize that personal information of customers and all other parties involved in our business activities should be handled appropriately and carefully under the Act on the Protection of Personal Information and the principle of respect for individual privacy. Based on the understanding that this is not only for compliance with laws and regulations, but also being closely related to the rights and interests of individuals, we pledge the following in connection with handing personal information.

We will comply with the Act on the Protection of Personal Information, guidelines in the economic and industrial field regarding the Act, and other related laws and regulations. We will also handle personal information appropriately in accordance with generally accepted practices.

We will clarify rules and regulations regarding the handling of personal information and ensure that all employees and other related persons comply with them. We also request our business partners etc. to handle personal information appropriately.

In handling personal information, we shall, in principle, specify a retention period within the scope necessary for the purpose of use, and delete personal information after the retention period has elapsed or the purpose of use has been achieved, except in cases where exceptions are permitted by law.

We will take necessary measures to prevent leakage, loss, falsification, etc. of personal information and manage it properly.

Requests by a person for disclosure, correction, deletion, or suspension of use of personal information in our possession will be accepted at the designated contact point and will be handled conscientiously.

Contact Us

Contact Us

[Important] Notice of Relocation

[Important] Notice of Relocation